NDE, QA, welding inspection and prefab audit to meet any project’s certification needs and timeframe.

25 years of industry knowledge: accurate, precise reports; industry-leading turnarounds. Anytime, anywhere.

Going the extra mile to meet each customer’s needs on-time, and build long-term customer relationships.

ASNT, SNT-TC-1A Certified Techs, AWS, QC-1 CWIs), ACCP Professional NDE Level III.

MIT was chosen in 2003 by a leading U.S. Port to perform Quality Assurance (QA), random Ultrasonic Testing (UT) and third party vendor surveillance during the manufacturing of Ship to Shore and Rubber Tired Gantry (RTG) Cranes.

Read More

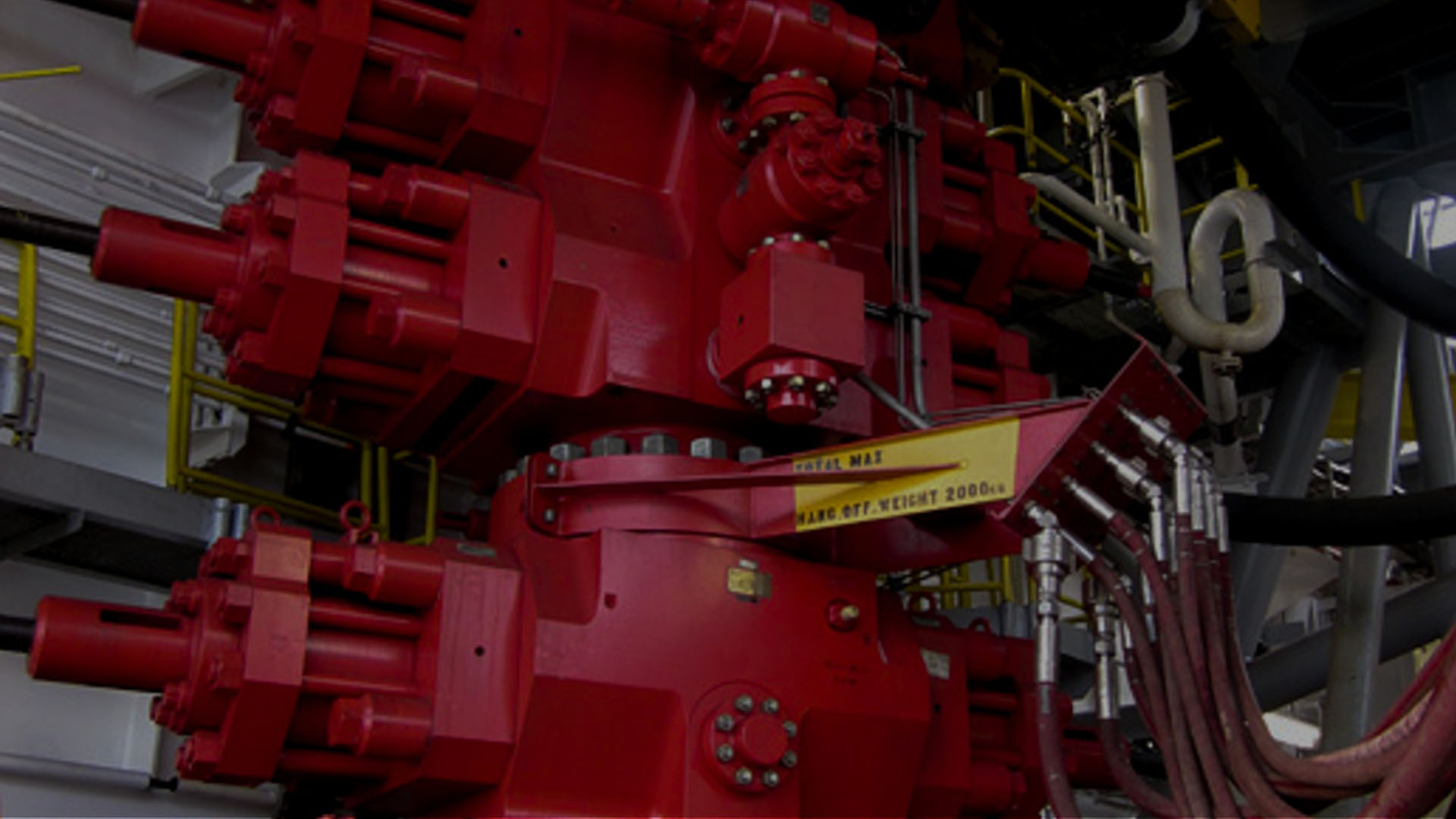

Material Inspection Technology provides an array of services to a leader in the subsea oil and gas hydraulic coupler industry.

Read More

In 2010 MIT won the bid to perform the Scheduled Maintenance Inspection of 4 ZPMC Ship To Shore cranes for a major United States Port.

Read MoreMaterial Inspection Technology has performed fabrication quality assurance inspections on the fabrication of several Rubber Tired Gantry (RTG) Cranes and Ship to Shore Cranes in Europe and China on numerous occasions. The Port of Houston Authority feels that MIT has PHA’s best interest at heart during these inspections and are knowledgeable of the product and inspection methods performed.” “During these inspections MIT monitored fabrication welding practices, performed visual welding inspections and Ultrasonic testing. The results of these inspections helped the outcome of the project by improving the quality of the complete cranes. ”

The Port of Houston Authority

“Material Inspection Technology is a subcontractor of ours that provides Certified Weld Inspectors to inspect commercial building projects in the Houston Area. Much of the time our scheduling is last minute due to the unpredictability of contractors, MIT always takes this in stride. MIT inspects the finish welds and bolting in accordance with the project specification and drawings. Their reports are neat and to the point. Their efforts are definitetly appreciated.”

Consultant Engineering Firm Houston, Texas

MIT has been on our Approved Vendors List for 4 years and has been an asset to our fabrication efforts. They provide Radiography, Ultrasonic, Liquid Penetrant and Magnetic Particle Testing. Our ASME program has benefited from MIT’s diversity. Recently we have used them to qualify our welders and write our PQR’s and WPS’s, which has also helped us free up our QA staff to focus on other duties. ”

Antonio JohnsASME Pressure Vessel Shop Houston, Texas